What is an Impact Driver?

An impact driver is a cordless drill driver with a 1/4″ hex bit holder that grabs tiny screwdriver bits instead of a typical 13mm chuck.

High-torque and high-impact are the hallmarks of impact drivers. Even the top-of-the-line cordless drill can’t match the torque output of a regular impact driver. You’ll be able to easily drive long, broad screws into even the toughest materials, thanks to the torque available to you.

The head length is another important feature and advantage to consider when purchasing a cordless impact driver. The shorter the head length, the better. This is because you’ll be operating your impact driver in tight and difficult areas at times. Impact drivers with a single-speed will be cheaper.

On the other hand, two or more gears are recommended for more precision, speed, and torque control. So, if speed/torque settings are important to you, search for an impact driver with at least two of them.

Contents

How does an impact driver work?

Impact wrenches hit the drive mechanism with a significant amount of power, then back up and put it again, as the name implies. Imagine if you’re trying to break down a brick wall with your automobile to comprehend this notion better. You could apply a certain degree of force on the wall if you crept up to it, touched it, and then applied the gas.

It may or may not move depending on the severity of the wall. However, if you backed up ten yards, slammed on the throttle, and crashed into the wall with speed and momentum, you’d have a far higher chance of having a substantial effect.

When comparing a drill with an impact wrench, the same principle applies. Drilling is similar to carefully pushing your automobile up to the wall and then putting on the throttle. The impact wrench is like slamming against the wall from 10 yards away. The repercussions are far more profound.

Pros and Cons of Impact Driver

The impact driver has a few flaws that help define its purpose and location in your toolkit. Impact drivers, unlike standard cordless drills, do not have adjustable chucks; thus, you won’t be able to utilise your old round bits. Impact drills, on the other hand, employ hex locking bits with a releasable ring on the drill’s tip or an anvil that takes sockets.

Another disadvantage is the absence of a clutch. When a conventional drill encounters a particular resistance level, the clutch will release the bit. This prevents screws from being bored excessively deep or stripped. Impact drivers are quick and powerful, and if you don’t use a clutch, you risk destroying a project you’re working on.

An impact driver appears to offer 100 advantages for every disadvantage. The torque produced by today’s low weight and strong 20V Lithium driver is roughly 325 in-lbs, whereas the torque produced by an impact wrench is around 1,600 in-lbs! A drill uses a great deal of power as it tries to generate maximum torque, which means you’ll have to change batteries more frequently.

You won’t have to deal with high-level torque while using an impact driver because the drill bit and motor aren’t directly linked. Because of the strong rotational force of an impact driver, you won’t have to apply as much power when driving screws. All of this translates to decreased muscular tension and fatigue. This may make a big impact on tasks that require a lot of screws, including deck construction, tile backer board installation, or subfloor installation.

What is a drill?

A drill is a tool that is used to create round holes and drive fasteners. It comes with a bit, which may be either a drill or a driver chuck. Hand-operated models are becoming less popular, while cordless battery-powered models are becoming more common.

Advantages of Using a Drill

Tools have the advantage of requiring less effort than earlier types. The chuck and spindle move as a result of the lever’s action on a pinion or rack, which gives the operator a stable mechanical advantage. The table allows a clamp to lock in place and secure the job, ensuring that the process is secure. The table’s spindle angle is set, allowing the holes to be drilled repeatedly and accurately.

Drill machines provide a high level of precision for drilling precise holes and repeat drilling operations. When compared to prior handheld drills, it requires minimal manual intervention to operate. It is powered by a motor that spins a belt that pressurises the drill bit at the highest possible speed.

The drill bit scrapes away any of the material when dropped into a piece of wood or metal, and the size varies on the drill bit sizes. The chuck that keeps the drill bit in place as it spins at the highest speed rate is secured by the spindle. The chuck is fastened to the drill with the use of a screwdriver-like instrument that shuts and unlocks the chuck’s cylinder.

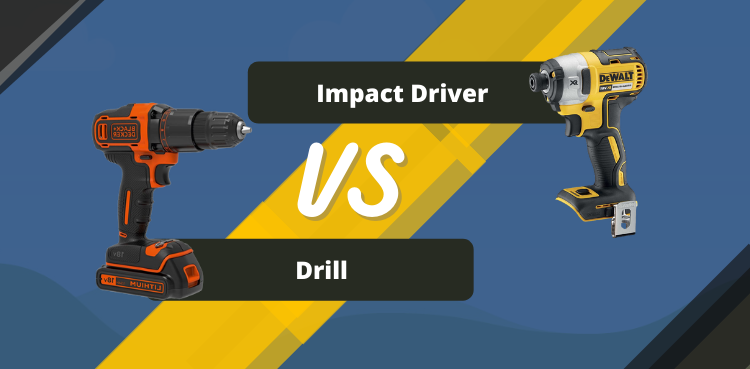

Impact Driver VS Drill

The drill driver is a high-performance power tool. It has been simplified and enhanced throughout the years. It no longer has a cord and has become as lightweight and dependable as possible.

We’ve used them for years to drive screws into any surface we choose with a smooth force; yet, the difficult operations often result in a weary wrist and a strip of screw heads.

The drill is versatile, having different speeds that come in useful when switching between drilling holes and driving screws in. The contemporary drill also includes an automated spindle lock that allows for rapid attachment changes.

Despite the resemblance of an impact driver to a drill driver, the impact driver functions differently and has several fancy enhancements over the standard drill.

To begin, it functions similarly to a standard drill, whether drilling a hole or driving a screw. Additionally, it may create more power when the impact driver detects resistance. This gives you more control and prevents your arms from fatiguing from holding things up. It also reduces the likelihood of squandering screws by stripping their heads.